Laser Cutting Guidelines

A well designed file meeting our cutting guidelines is the key to getting your parts fast. Be sure to review all our guidelines before you place an order.

We’re here to help support@readysetcut.ca

A well designed file meeting our cutting guidelines is the key to getting your parts fast. Be sure to review all our guidelines before you place an order.

We’re here to help support@readysetcut.ca

Units

Your drawing must be either imperial (inches) or metric (mm). We do not accept cm or meter units.

Scale

Your design should be correctly scaled. All drawings must be 1:1 scale . Any written notes regarding scale will be ignored.

Notes & Extra Lines

Please remove any notes, dimensions, or extra lines. They may be picked up as a cut path and result in a higher part price.

1:1

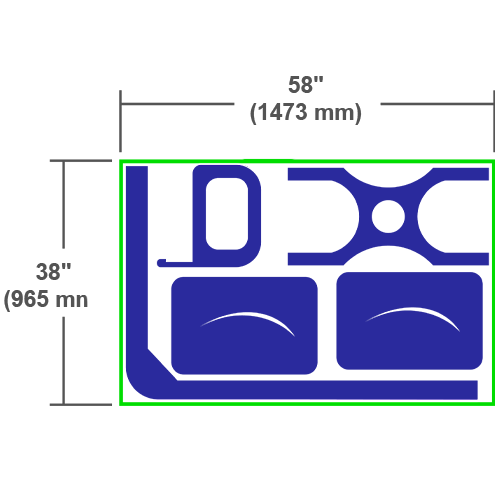

Our current cutting area is 58″ (1473 mm) x 38″ (965 mm). Please make sure your part(s) will fit within the cutting area. Parts that are larger then our cutting area will produce an error when quoting.

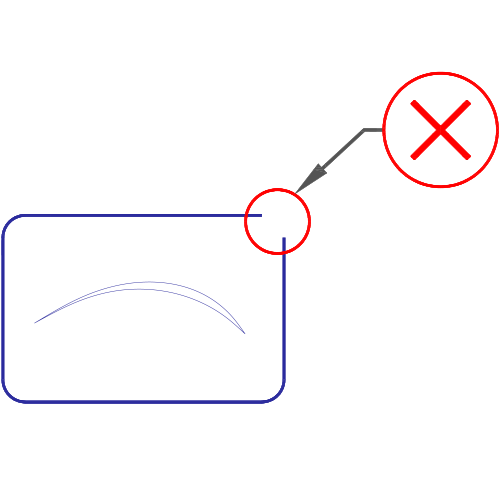

The laser uses your lines as it cutting path. Make sure that your design doesn’t have any broken paths, missing lines, intersecting or overlapping lines. Open contours, intersecting and overlapping lines can increase lead time and increase cost as your file would have to be revised before manufacturing.

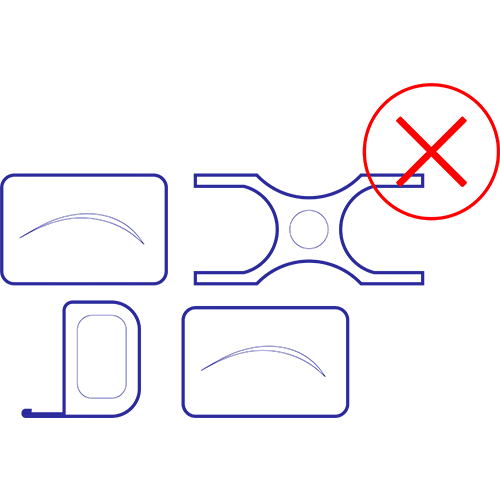

Your file should only contain one part and should only contain the cut path of the part and no other details. Be sure to remove title blocks, notes, dimensions, and any entities that are not the cut path.

All lines/entities should be on the same layer.

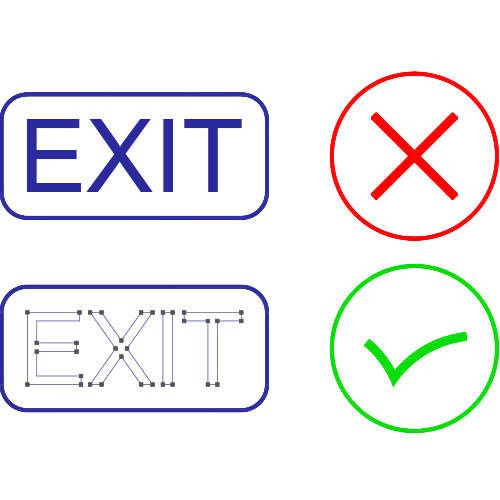

Text and text boxed need to be converted to shapes or outlines. Watch the small pieces! Make sure to bridge the center sections of the text or shapes if you don’t want them to be loose.

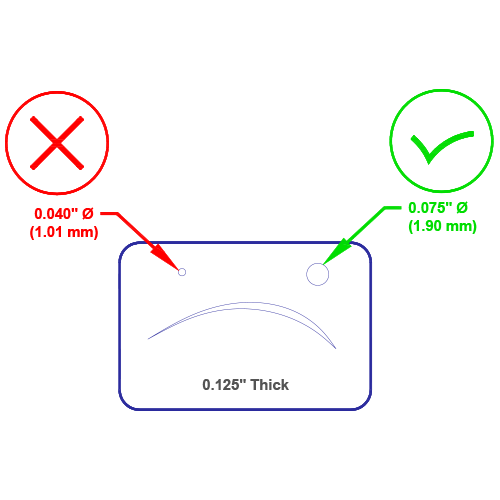

Standard practice for a good quality part is to keep the diameter of a hole or cutout a minimum of 60% of the material thickness. For example; For 0.120” (3mm) thick material the minimum recommended hole diameter would be 0.072” (1.8mm).